What is Polybutylene Pipe: Everything You Need to Know

Contents

- 1 What is Polybutylene Pipe: Everything You Need to Know

- 1.1 Key Takeaways

- 1.2 Understanding Polybutylene Pipes

- 1.3 Identifying Polybutylene Pipes

- 1.4 Risks Associated with Polybutylene Pipes

- 1.5 Lawsuits and Legal Issues

- 1.6 Replacing Polybutylene Pipes

- 1.7 Professional Assistance

- 1.8 Summary

- 1.9 About K L Contractor Plumbing Inc. – Marietta’s Neighborhood Plumber

- 1.10 Frequently Asked Questions

- 1.10.1 What are polybutylene pipes made from?

- 1.10.2 Why did polybutylene pipes fall out of favor?

- 1.10.3 How can I identify polybutylene pipes in my home?

- 1.10.4 What are the costs associated with replacing polybutylene pipes?

- 1.10.5 Why is it important to hire a licensed plumber for polybutylene pipe replacement?

Polybutylene pipes, commonly known as PB pipes, were used extensively in residential plumbing systems from the 1970s to the 1990s because they were introduced as a cheaper alternative to traditional plumbing materials like copper, making them attractive for cost-conscious builders and homeowners. Despite their initial popularity, these pipes are now infamous for their tendency to deteriorate and leak due to chemical reactions with water disinfectants. In this article, we’ll cover the history, identification, risks, and replacement of polybutylene pipes, specifically addressing what is polybutylene pipe and its implications for homeowners.

Key Takeaways

Polybutylene pipes, once popular for their affordability and flexibility, are no longer sold in the U.S. due to a high risk of leaks and property damage.

Homeowners should identify polybutylene pipes by their distinct characteristics and consult professional plumbers for assessment and potential replacement to avoid plumbing disasters.

Replacement of polybutylene pipes with safer alternatives like PEX or copper is essential to prevent extensive property damage, mitigate insurance challenges, and ensure compliance with plumbing standards.

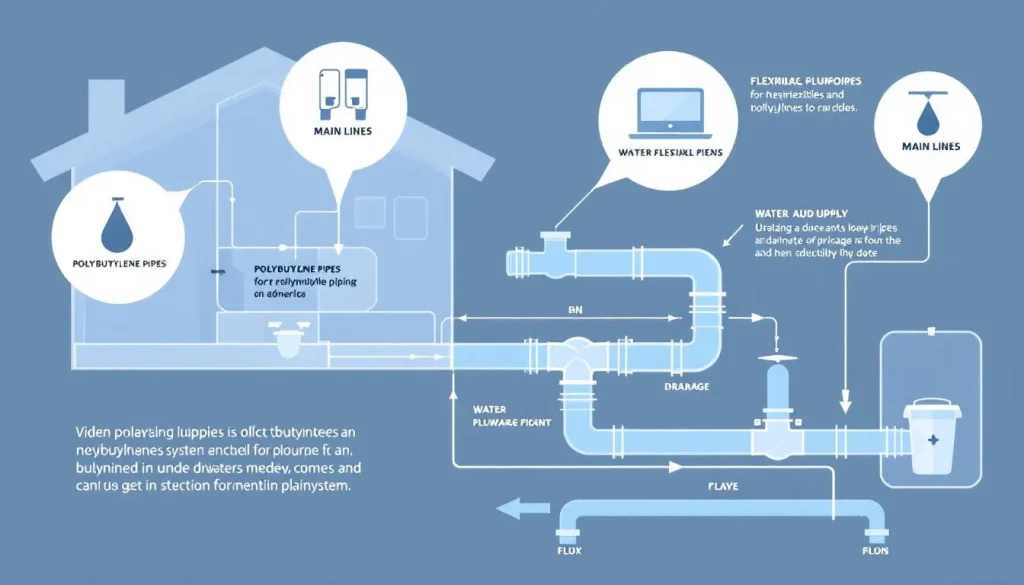

Understanding Polybutylene Pipes

Polybutylene pipes, commonly referred to as PB pipes, are made from a plastic resin that was once considered a breakthrough in plumbing materials. These pipes were predominantly used from the late 1970s to the mid-1990s due to their flexibility, which made them easy to install, especially compared to traditional materials like copper. However, despite their initial popularity, polybutylene pipes are no longer sold in the United States due to their susceptibility to deterioration and failure. Production of polybutylene pipes ceased after widespread failures and resulting lawsuits highlighted significant safety concerns. Additionally, pb piping has been a topic of concern in discussions about plumbing safety.

The story of polybutylene pipes is a classic tale of innovation met with unforeseen challenges. Their decline was almost as swift as their rise, driven by numerous reports of leaks and property damage, leading to a wave of lawsuits and a significant shift in the plumbing industry. Understanding this history is crucial for anyone dealing with older home plumbing systems, as many have experienced the consequences when these pipes fail.

The Rise of Polybutylene Pipes

During the 1980s, polybutylene pipes were marketed as the ‘pipe of the future’ due to their affordability and ease of installation. They were significantly cheaper than copper pipe, making them an attractive option for builders and homeowners alike. The flexibility of PB pipes allowed for quicker and less expensive installations, which contributed to their widespread use in residential plumbing.

It is estimated that between 6 to 10 million homes were built using polybutylene pipes, highlighting their significant impact on the housing market during that period. Their initial success was largely due to the perceived benefits of cost-effectiveness and longevity, which unfortunately did not pan out as expected in the long run.

The Decline of Polybutylene Pipes

The decline of polybutylene pipes began in the mid-1990s, triggered by numerous reports of microfractures and failures due to chemicals reactions with oxidants and disinfectants like chlorine. These reactions caused the pipes to deteriorate, leading to leaks and bursts that resulted in extensive property damage.

By 1995, multiple lawsuits against polybutylene pipe manufacturers led to their significant decline. The legal battles and mounting evidence of their unreliability marked the end of the era for polybutylene piping in the United States.

Identifying Polybutylene Pipes

Identifying polybutylene pipes is crucial for homeowners to avoid plumbing disasters. Key characteristics include:

Made from a flexible plastic resin, distinguishing them from more rigid materials like copper

Typically last between 10 to 15 years before they start to deteriorate

Pose a risk of leaks or bursts as they age

Polybutylene pipes are used exclusively for water supply lines and are not used for drain, waste, or vent piping. Specific fittings, such as acetal fittings, were used to connect polybutylene pipes, and compatibility issues with these fittings contributed to plumbing failures.

Plumbers can accurately identify polybutylene pipes and recommend options to replace polybutylene pipes. If you suspect your home has these pipes, seek professional advice to prevent plumbing issues and property damage.

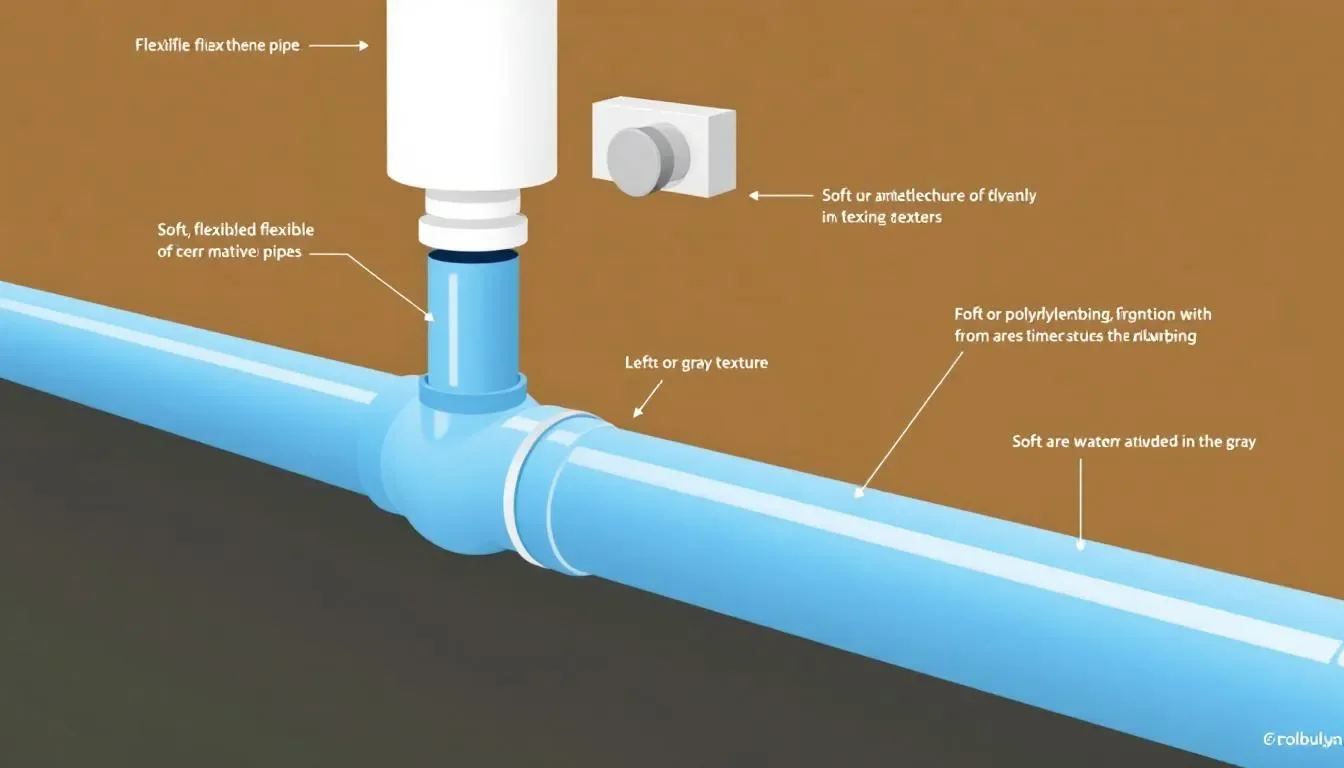

Key Features to Look For

Polybutylene pipes can be identified by their various colors, including gray, white, silver, black, and blue, with gray being the most common. These pipes are often stamped with markings like ‘PB2110’, which can help in identifying the type of pipe you are dealing with.

Polybutylene pipe stub outs may also be visible near fixtures or where pipes transition to copper, providing another clue for identification.

The most common diameters for polybutylene pipes range from ½ inch to 1 inch. If you come across flexible pipes with these characteristics in your home, it’s a red flag that warrants further inspection by a professional plumber.

Common Installation Locations

Polybutylene pipes are commonly found in various locations throughout the interior of the home. They often run across ceilings in unfinished basements, may be visible near the basement wall, and enter the home through walls near the water shut off valve or shut-off valves. These pipes are frequently connected to sinks, toilets, water heater, and water heaters, making these fixtures key inspection points. Additionally, polybutylene pipes may enter the home near the water main or water meter, which are important areas to check for their presence.

Being aware of common installation locations helps identify potential problem areas in your home plumbing system. A thorough inspection of the following locations by a professional plumber can confirm the presence of polybutylene pipes that have been installed and guide you on the next steps.

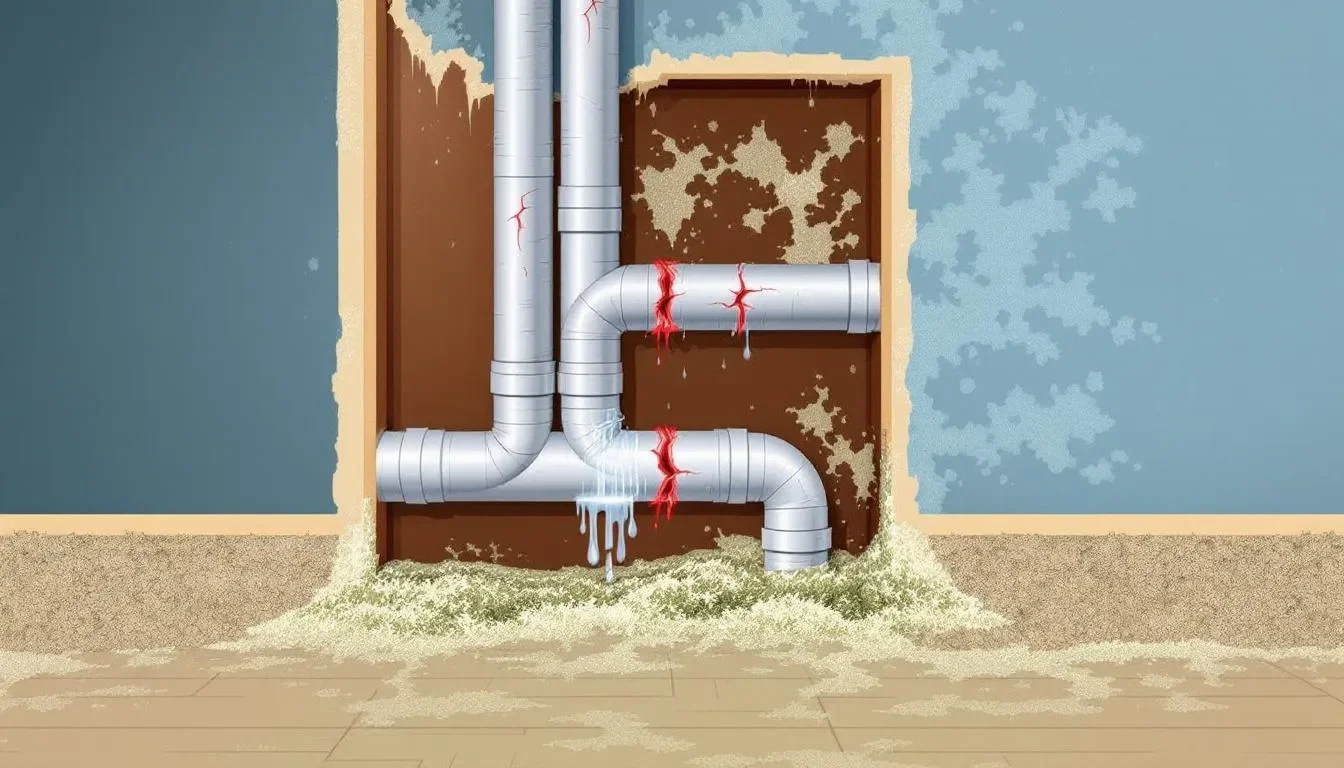

Risks Associated with Polybutylene Pipes

The risks associated with polybutylene pipes are significant, primarily due to their tendency to develop leaks, joint failures, and potential bursts. These issues are often caused by chemical reactions with disinfectants like chlorine, which can weaken the pipes over time. A sudden burst in polybutylene pipes can lead to extensive property damage and costly repairs.

Selecting reliable piping materials is crucial to prevent leaks, failures, and property damage associated with inferior or outdated piping materials.

Hidden leaks are also a concern, as they can result in water pooling, mold growth, and structural material damage to your house. Homeowners should be proactive in addressing these exposed risks to protect their property and health.

Water Damage and Mold Growth

Leaks from polybutylene pipes can lead to severe water damage and mold growth. Experiencing water damage from leaking polybutylene pipes necessitates stopping work immediately, saving all materials, and filing a claim with your homeowner’s insurance.

Replacing polybutylene piping due to water damage can cost several thousand dollars. Prompt action is necessary to mitigate the damage and prevent further issues, highlighting the importance of regular inspections and timely repairs.

Higher Insurance Premiums

Insurance companies often view homes with polybutylene pipes as high-risk, leading to higher premiums and potential coverage difficulties. Insurance companies may impose higher premiums or outright exclusions for properties with polybutylene plumbing due to the high risk of damage.

Homeowners should consider replacing these pipes replaced to lower their insurance costs and avoid coverage challenges.

Lawsuits and Legal Issues

The issues with polybutylene pipes have led to significant legal challenges, including multiple class-action lawsuits in the 1990s. These lawsuits highlighted the widespread failures of polybutylene pipes and resulted in substantial settlements for affected homeowners.

Homeowners with polybutylene pipes often face challenges when selling their homes, as potential buyers may request the replacement of the pipes due to their known issues. Homeowners dealing with polybutylene pipes should understand the legal landscape and outcomes of these lawsuits.

Cox vs. Shell Oil Co.

The Cox vs. Shell Oil Co. class action lawsuit was a landmark case that resulted in a $950 million settlement for homeowners, providing free replacements for polybutylene pipes. This lawsuit was pivotal in highlighting the collective legal response to the failures of polybutylene pipes, influencing future claims and setting a precedent for similar cases.

The settlement provided significant relief for affected homeowners and underscored the importance of addressing polybutylene pipe issues.

Spencer vs. Shell Oil Co.

The Spencer vs. Shell Oil Co. lawsuit emerged in 2017 as a continuation of the legal challenges surrounding polybutylene pipes. The outcomes of lawsuits like Spencer vs. Shell Oil Co. can significantly impact homeowners’ perceptions and decisions regarding polybutylene pipe replacements. Ongoing legal challenges continue to affect homeowners’ rights to claim damages, emphasizing the need for awareness and proactive action.

Replacing Polybutylene Pipes

Replacing polybutylene pipes is essential to prevent significant issues, including flooding and serious damage to the property. PEX is commonly used as a replacement because it is made from cross linked polyethylene, which provides superior flexibility and durability compared to older materials like polybutylene. Conducting a replacement and having a licensed plumber inspect their condition can extend the life of your plumbing systems by 50 or more years.

Certified plumbers accurately identify polybutylene pipes and determine the best replacement strategy. If polybutylene pipes are found in your home, immediate replacement is necessary to avoid further complications.

Cost of Replacement

The cost of replacing polybutylene pipes can vary significantly:

A full home repipe with polybutylene pipes can potentially reach up to $15,000.

Replacing these pipes with PEX or PVC typically costs around $10,000.

Copper piping replacement can be even more expensive.

Selecting replacement pipes involves considering your budget, specific plumbing needs, and local building codes. Investing in polybutylene pipe replacement can prevent future property damage and costly repairs.

Replacement Materials

Several materials and other materials are suitable for replacing polybutylene pipes, including CPVC, PEX, and copper. PEX pipes, in particular, are known for their flexibility, durability, and resistance to scale buildup and corrosion. PVC pipes are also suitable for both cold and hot water applications, making them versatile for various plumbing needs.

PEX pipes have several advantages over polybutylene piping:

They can withstand high temperatures.

They are less prone to freezing or bursting.

They are more flexible.

They come in vibrant colors, making installation easier.

Professional Assistance

Hiring a professional plumber ensures safety and code compliance when identifying and replacing polybutylene pipes. To find a licensed plumber, seek recommendations, check online reviews, and verify credentials through local licensing boards.

A professional plumber‘s thorough inspection can identify the presence and condition of polybutylene pipes, preventing future plumbing issues. Ensuring that the plumber is licensed and insured before hiring them is critical to guarantee quality work.

Finding a Licensed Plumber

Finding a qualified plumber includes seeking referrals, checking online directories, and reading reviews. Contacting a home inspector or scheduling an online home inspection can also help in identifying polybutylene pipes.

Hiring a licensed plumber ensures proper assessment and replacement of polybutylene pipes, safeguarding your home plumbing systems from future issues.

Inspection and Assessment

A licensed plumber’s thorough inspection can detect hidden polybutylene pipes. Professional assessments often involve using specialized tools to detect hidden leaks and evaluate the integrity of polybutylene piping.

After inspection, plumbers may recommend immediate replacement if significant deterioration is found. Always verify a plumber’s credentials and insurance before hiring them for polybutylene pipe replacement to ensure quality work. If the polybutylene pipe is found to be damaged, it should be replaced.

Summary

Polybutylene pipes, once hailed as the future of plumbing, have proven to be a costly mistake for many homeowners. Understanding their history, identifying their presence, and knowing the risks they pose are crucial steps in protecting your property. The significant legal battles and the high costs associated with replacing these pipes highlight the importance of proactive action.

Replacing polybutylene pipes with more reliable materials like PEX, CPVC, or copper can prevent future damage and reduce insurance premiums. Hiring a professional plumber for inspection and replacement ensures that the job is done correctly and in compliance with building codes. Taking these steps can safeguard your home and give you peace of mind.

About K L Contractor Plumbing Inc. – Marietta’s Neighborhood Plumber

K L Contractor Plumbing Inc. proudly serves homeowners across Marietta, GA, and the surrounding communities, offering trusted plumbing solutions backed by years of hands-on experience and local expertise. Known as Marietta’s Neighborhood Plumber, we’re committed to protecting Georgia homes from plumbing problems that can lead to costly repairs — including issues caused by polybutylene pipes, outdated fixtures, and hidden leaks.

Our licensed plumbers specialize in whole-home repiping, polybutylene pipe replacement, and water line upgrades, ensuring that every home we service meets today’s safety and plumbing standards. We’ve helped countless homeowners throughout Cobb County, including Kennesaw, Smyrna, Acworth, and East Cobb, replace failing PB piping systems with modern, reliable materials like PEX and copper.

At K L Contractor Plumbing Inc., we understand how stressful plumbing failures can be. That’s why our team delivers honest assessments, upfront pricing, and high-quality workmanship that lasts. Whether you’re dealing with water pressure issues, hidden leaks, or deteriorating pipes, our experts provide the right fix — done the right way, the first time.

Our full range of plumbing services includes:

Polybutylene pipe inspection and repiping

Water heater repair and installation

Sewer and water line repair

Fixture and faucet replacement

As a locally owned and operated plumbing company, we take pride in helping our Marietta neighbors keep their homes safe, efficient, and up to code. We treat every property as if it were our own delivering dependable plumbing solutions backed by integrity and care.

For expert plumbing service or to schedule a polybutylene pipe inspection in Marietta, call K L Contractor Plumbing Inc. today at 470-694-6599

K L Contractor Plumbing Inc. keeping homes across Marietta, Kennesaw, Acworth, and the Greater Atlanta area leak-free, secure, and built to last.

Frequently Asked Questions

What are polybutylene pipes made from?

Polybutylene pipes are made from plastic resin, known for being a revolutionary plumbing material. This synthetic polymer contributed to their widespread use in construction and plumbing systems.

Why did polybutylene pipes fall out of favor?

Polybutylene pipes are no longer favored because they are prone to leaks and bursts from chemical reactions with disinfectants, which can result in extensive property damage. This reliability issue has led to their decline in use.

How can I identify polybutylene pipes in my home?

You can identify polybutylene pipes by their flexible plastic composition and by looking for markings such as ‘PB2110’. Most commonly, these pipes are grey, which can help you distinguish them from other types.

What are the costs associated with replacing polybutylene pipes?

Replacing polybutylene pipes can cost between $10,000 and $15,000, influenced by the materials chosen and the scope of the plumbing work required. It’s essential to budget accordingly to address this significant expense.

Why is it important to hire a licensed plumber for polybutylene pipe replacement?

Hiring a licensed plumber for polybutylene pipe replacement is crucial because it guarantees compliance with building codes and prevents future plumbing issues, ensuring safety and efficiency in your home’s plumbing system.