Home Buying Plumbing Inspection Checklist: 12 Must-Check Items for Marietta Homebuyers

Contents

- 1 Home Buying Plumbing Inspection Checklist: 12 Must-Check Items for Marietta Homebuyers

- 1.1 Why Standard Home Inspections Miss Critical Plumbing Problems

- 1.1.1 1. Water Pressure Testing Throughout the Home

- 1.1.2 2. Water Heater Age, Condition, and Performance

- 1.1.3 3. Drain Performance and System Inspection

- 1.1.4 4. Visible Pipe Materials and Condition

- 1.1.5 5. Toilet Function and Common Problems

- 1.1.6 6. Faucet and Fixture Leak Detection

- 1.1.7 7. Water Supply Line Integrity

- 1.1.8 8. Sewer Line Inspection and Functionality

- 1.1.9 9. Water Quality and Discoloration Issues

- 1.1.10 10. Garbage Disposal Operation and Safety

- 1.1.11 11. Sump Pump Function and Backup Systems

- 1.1.12 12. Gas Line Safety and Condition

- 1.2 When to Schedule Your Plumbing Inspection

- 1.3 What Professional Plumbing Inspections Include

- 1.4 Negotiating Repairs After Your Inspection

- 1.5 Moving Forward With Confidence

- 1.1 Why Standard Home Inspections Miss Critical Plumbing Problems

Buying a home in Marietta represents one of the biggest financial decisions you’ll ever make. While fresh paint and modern kitchens catch your eye during showings, your plumbing system hidden behind those walls determines whether your dream home becomes a money pit.

Most homebuyers focus on cosmetic features and overlook critical infrastructure until problems surface after closing. By that point, you’ve already committed to expensive repairs that could have been negotiated before purchase or avoided entirely.

A thorough home buying plumbing inspection protects your investment by revealing issues that standard property evaluations often miss. This comprehensive checklist covers the 12 most critical areas that determine your home’s condition and whether you’re buying a solid property or inheriting someone else’s headaches.

Why Standard Home Inspections Miss Critical Plumbing Problems

General home inspectors evaluate hundreds of components during a typical walk-through. They check electrical systems, structural integrity, roofing, HVAC, and dozens of other elements in just a few hours.

While competent inspectors identify obvious plumbing issues, they rarely have specialized knowledge to detect subtle warning signs. They can’t perform invasive tests that reveal hidden leaks behind walls or underground.

Many serious defects remain invisible during standard property assessments. Slow leaks inside walls, deteriorating sewer lines, and failing water heaters may show no obvious symptoms until they catastrophically fail.

K L Contractor Plumbing Inc specializes in comprehensive pre-purchase evaluations that go beyond what general home inspectors provide. With 26 years of experience serving Marietta homeowners, our licensed professionals use specialized equipment to identify any issues before they become your financial burden.

1. Water Pressure Testing Throughout the Home

Low water pressure signals potential problems ranging from simple fixes to expensive pipe replacements. Testing pressure in multiple locations reveals whether issues affect the entire house or specific areas.

What to Check:

- Turn on multiple faucets simultaneously to test system capacity

- Check upstairs and downstairs fixtures separately

- Flush toilets while showers run to identify pressure drops

- Test outdoor hose connections for adequate flow

- Note whether pressure decreases during peak usage times

Inconsistent pressure often indicates corroded pipes, hidden leaks, or undersized supply lines. Older Marietta homes built before 1970 frequently have galvanized pipes that corrode internally and restrict flow.

Whole-house pressure issues may stem from problems at the main line connection or pressure regulator failure. Single-fixture problems typically point to clogged aerators or localized pipe issues.

During professional plumbing inspection, technicians measure actual pressure with gauges rather than relying on subjective assessments. Normal residential pressure ranges from 40 to 60 PSI – anything significantly outside this range requires investigation and helps them determine whether simple repairs solve the issue or complete repiping becomes necessary.

2. Water Heater Age, Condition, and Performance

Water heaters typically last 8-12 years for traditional tank models and 15-20 years for tankless systems. A failing unit represents an immediate expense after closing that most homebuyers don’t anticipate.

Critical Assessment Points:

- Check the manufacturer’s date on the rating plate

- Look for rust, corrosion, or moisture around the base

- Test hot water temperature and recovery time

- Inspect the pressure relief valve for proper operation

- Examine venting systems for gas models

- Verify electrical connections on electric units

Age tells you whether replacement looms in your near future. A 10-year-old tank unit approaching the end of its service life should factor into your purchase negotiations.

Rust-colored output or sediment buildup indicates internal tank corrosion. Once corrosion begins, failure becomes inevitable – it’s a matter of when, not if. The water heater cannot recover from internal deterioration.

Test capacity by running multiple fixtures simultaneously. If the shower turns cold after 10 minutes, the heater cannot meet the home’s demands. This signals undersized equipment or a failing heating element that needs replacement.

3. Drain Performance and System Inspection

Slow drains that homeowners dismiss as minor annoyances often signal serious underlying problems. What seems like a simple clog may actually indicate damaged sewer lines or systemic drainage issues that require professional repair.

Drainage Testing Checklist:

- Run all sinks for 2-3 minutes continuously

- Fill bathtubs and watch drain speed when released

- Flush every toilet and observe bowl refill

- Test floor drains in basements and garages

- Listen for gurgling sounds during drainage

- Check for standing moisture around outdoor drains

Multiple slow drains throughout the home suggest main sewer line problems rather than isolated clogs. This pattern indicates potential tree root intrusion, pipe collapse, or severe blockages that affect the entire system.

Gurgling sounds when draining point to venting issues or partial blockages. Proper drain systems should operate silently – unusual noises indicate air displacement caused by obstructions somewhere in the line.

Standing moisture near foundation drains reveals drainage system failures that could cause serious structural damage. These issues require immediate attention before they compromise the home’s foundation and create expensive repair needs.

Professional plumbing inspection can include video camera examinations of sewer lines to identify hidden problems. This technology reveals tree root intrusion, pipe deterioration, and blockages that visual assessment cannot detect from the surface.

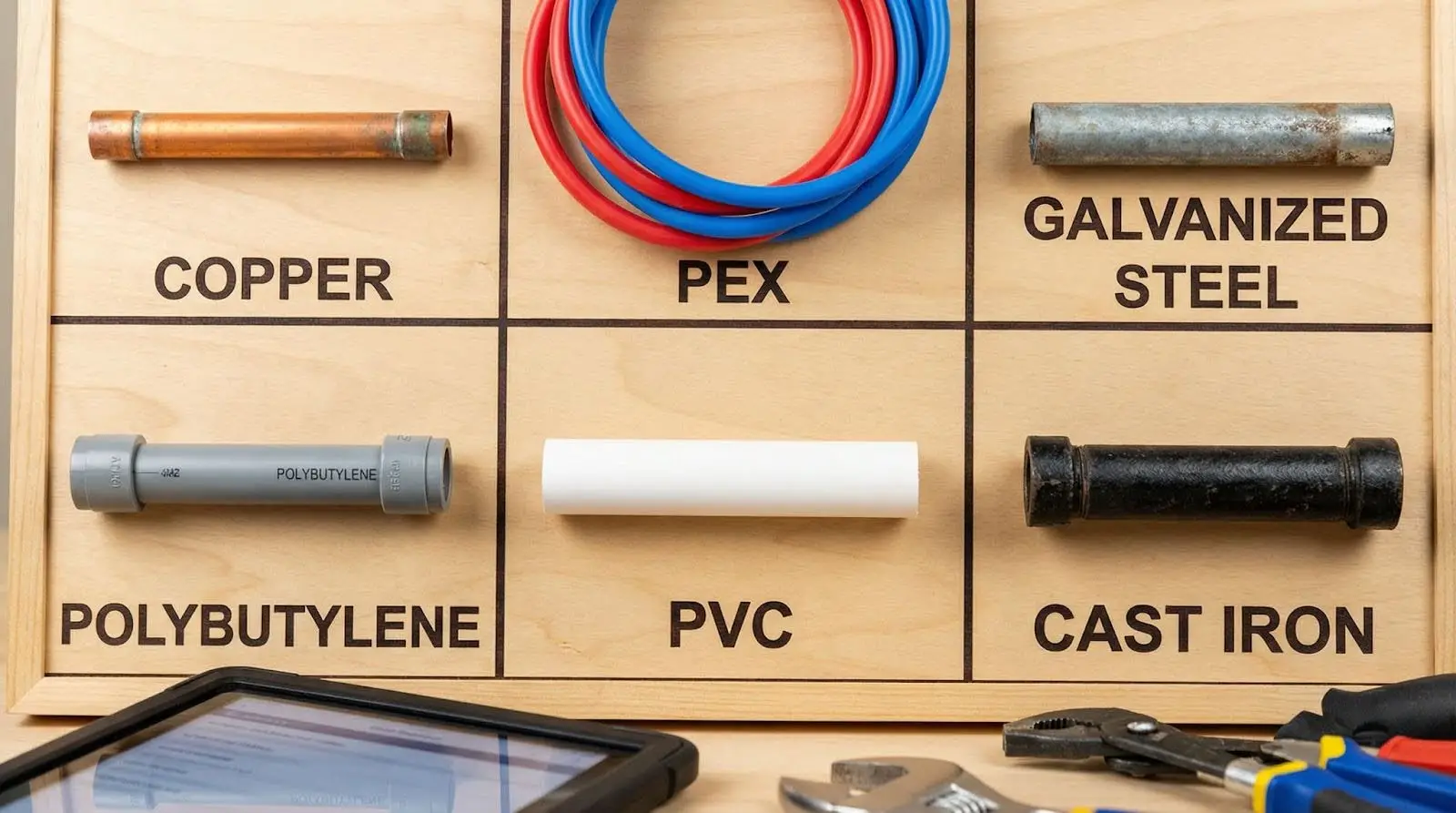

4. Visible Pipe Materials and Condition

The pipes throughout a home determine system reliability for decades. Certain materials common in older Marietta homes create predictable problems that require expensive correction down the road.

Pipe Material Assessment:

- Identify supply pipe materials (copper, PEX, galvanized, polybutylene)

- Check drain pipe materials (PVC, cast iron, ABS)

- Look for corrosion, leaks, or repairs on exposed pipes

- Examine pipe joints and connections for moisture

- Note any temporary repairs or patches

Polybutylene pipes installed between 1978 and 1995 have documented failure rates that insurance companies recognize as high-risk. These gray plastic pipes become brittle and crack without warning, causing extensive damage. Homes with polybutylene require complete repiping to eliminate the failure risk.

Galvanized steel pipes common in pre-1960 homes corrode internally and restrict flow over time. While they may appear fine externally, internal corrosion reduces pipe diameter and decreases pressure throughout the house gradually over years.

Cast iron drain pipes typically last 50-75 years before deteriorating from the inside out. If the home was built in the 1960s or earlier, these pipes may approach the end of their service life even if they currently function properly without obvious problems.

Green stains on copper pipes or white mineral deposits indicate active leaks or chronic moisture problems. These visible signs reveal issues that require immediate repair before they cause extensive property damage.

5. Toilet Function and Common Problems

Toilets that “work fine” during quick showings often have hidden issues that surface during daily use. These problems range from minor adjustments to complete replacement depending on severity.

Comprehensive Toilet Testing:

- Flush each fixture multiple times and watch bowl refill

- Check for leaks around the base after flushing

- Listen for continuous running after flush cycle completes

- Test stability by checking for movement or rocking

- Inspect tank components for wear or corrosion

- Verify proper flush strength and bowl clearing

Toilets that rock or move when pressure is applied indicate failed wax ring seals. These seals prevent sewer gas from entering the home and keep wastewater from leaking under the fixture onto the subfloor.

Continuous running after flushing wastes significant volume and signals worn internal components. Flappers, fill valves, and flush valves deteriorate over time and require replacement to restore proper function.

Weak flushes or incomplete bowl clearing suggest venting problems, partial clogs, or design issues. Modern low-flow toilets should clear the bowl completely in a single flush without requiring multiple attempts.

6. Faucet and Fixture Leak Detection

Small drips that seem insignificant waste thousands of gallons annually and indicate worn components that will worsen over time. Fixture leaks also reveal quality issues that corrode internal parts prematurely.

Fixture Assessment Protocol:

- Test every faucet in the home for drips and leaks

- Check under sinks for moisture or damage

- Operate all handles to assess smooth function

- Look for corrosion or mineral buildup on fixtures

- Test shower diverters and tub spouts for proper operation

- Inspect shower heads for leaks or poor spray patterns

Dripping faucets may seem minor, but they indicate worn washers, O-rings, or cartridges that will continue deteriorating. A faucet dripping once per second wastes over 3,000 gallons per year and drives up water bills unnecessarily.

Stains or warped cabinet materials under sinks reveal chronic leaks that may have already caused hidden damage. Inspect inside all sink cabinets with a flashlight, checking pipes, connections, and cabinet floors for moisture evidence that indicates ongoing problems.

Corrosion on finishes or mineral buildup around connections indicates hard supply or chemical imbalances. While not immediate failures, these conditions accelerate wear and reduce service life significantly.

7. Water Supply Line Integrity

Supply lines connect fixtures to your plumbing system. These small but critical components fail regularly and cause significant damage when they rupture unexpectedly under normal household pressure.

Supply Line Assessment Points:

- Check supply lines under every sink and toilet

- Look for braided stainless steel versus rubber hoses

- Examine connection points for corrosion or moisture

- Test shutoff valves for proper operation

- Verify supply lines have adequate length without stress

- Note the age and condition of all visible lines

Rubber supply hoses deteriorate over time and should be replaced every 3-5 years as preventive maintenance. Braided stainless steel lines offer better reliability but still fail eventually at connection points where corrosion occurs.

Shutoff valves that haven’t been operated in years often seize in the open position. Test every valve during your plumbing inspection – if they won’t turn, they need replacement before a fixture leak occurs and you can’t stop the flow.

Supply lines under tension or stretched to maximum length are more prone to failure. Proper installations include slight slack to accommodate normal movement without stressing connections or creating weak points.

8. Sewer Line Inspection and Functionality

The main sewer line carrying waste from your home to the municipal system operates underground where problems hide until major failures occur. A sewer line inspection using camera technology reveals issues before they become emergencies.

Sewer Line Evaluation:

- Request professional camera sewer line inspection

- Identify pipe material and approximate age

- Look for tree root intrusion or vegetation near sewer path

- Check for slow drains throughout the entire house

- Ask about previous sewer backups or problems

- Verify location of sewer cleanout access

Tree roots seeking moisture naturally infiltrate sewer lines through tiny cracks or joints. Once inside, roots grow extensively and create complete blockages requiring expensive repair or replacement of entire sections.

Cast iron and clay sewer pipes common in older Marietta homes deteriorate over time. Sections may collapse, separate at joints, or develop significant cracks that allow soil infiltration and create major blockages.

Video camera technology definitively reveals sewer line condition without excavation. This service typically costs a few hundred dollars but can save you from discovering tens of thousands in replacement needs after closing on the property.

K L Contractor Plumbing Inc provides comprehensive sewer line inspection services using advanced camera equipment. If problems surface, we can accurately estimate repair or replacement costs before you finalize the purchase.

9. Water Quality and Discoloration Issues

Quality problems indicate pipe corrosion, municipal supply issues, or contamination that affects your health and system longevity over time.

Quality Testing Protocol:

- Run cold supply for 2 minutes and check clarity

- Test hot supply separately for discoloration

- Look for sediment in toilet tanks

- Check for reddish-brown, green, or black stains

- Smell for sulfur, chlorine, or chemical odors

- Ask sellers about softener or filtration systems

Reddish-brown output indicates iron presence from corroding pipes or municipal supply issues. While not immediately dangerous, iron staining ruins fixtures, clothing, and components over time through permanent discoloration.

Green stains on sinks and tubs reveal copper pipe corrosion caused by acidic conditions. This accelerates pipe deterioration and will eventually cause pinhole leaks in copper supply lines throughout the house.

Black sediment in toilet tanks suggests manganese, decomposing rubber parts, or severe corrosion. This material clogs aerators and damages fixture components, reducing their operational lifespan significantly.

10. Garbage Disposal Operation and Safety

Garbage disposals require proper installation and venting to function safely. A malfunctioning disposal creates immediate inconvenience and may indicate larger drain system problems.

Disposal Evaluation:

- Test operation with cold flow running

- Listen for unusual grinding or rattling sounds

- Check for leaks under the sink during operation

- Verify reset button hasn’t tripped

- Test the grinding capability

- Examine electrical connections for safety

Disposals that hum but don’t grind have jammed impellers or motor failures. While sometimes fixable by pressing the reset button, chronic jamming indicates a unit approaching the end of its service life.

Units older than 10-12 years should be considered for replacement regardless of current function. Modern disposals operate more quietly, grind more efficiently, and include better safety features than older models.

11. Sump Pump Function and Backup Systems

Homes with basements or crawl spaces require functioning sump pump systems to prevent flooding during heavy rainfall. A failed pump during storms causes thousands of dollars in damage.

Sump Pump Assessment:

- Pour liquid into the sump pit to trigger the pump

- Verify the pump activates automatically

- Check discharge line routing and function

- Test backup battery system if installed

- Examine the pit for debris or sediment buildup

- Note pump age and manufacturer

Pumps that don’t activate when liquid reaches the trigger level have failed float switches or motor problems. These units provide no protection and must be replaced immediately to prevent flooding.

Discharge lines that route moisture back toward the foundation defeat the pump’s purpose entirely. Proper discharge lines carry flow at least 10 feet from the foundation to protect structural integrity.

Backup battery systems ensure pump operation during power outages when basement flooding risk peaks. Homes without battery backup face flooding during severe storms that knock out electricity.

K L Contractor Plumbing Inc installs, repairs, and maintains sump pump systems throughout Marietta. If your assessment reveals pump problems, we can provide complete replacement with proper discharge routing and battery backup.

12. Gas Line Safety and Condition

Natural gas lines supplying furnaces, heaters, ranges, and fireplaces require professional assessment for safety. Gas leaks create immediate danger and require specialized detection equipment to identify.

Gas Line Safety Check:

- Request professional gas line evaluation

- Check for sulfur odor near gas appliances

- Verify gas appliances have proper venting

- Examine visible gas lines for corrosion or damage

- Test gas appliance operation

- Confirm carbon monoxide detectors are installed

Gas leaks don’t always produce the characteristic sulfur odor, especially with small leaks that release minimal volume. Professional assessment using electronic detection equipment identifies leaks that noses can’t smell.

Corroded connections or damaged flexible connectors create serious safety hazards that endanger occupants. These components must be replaced immediately – there’s no acceptable level of deterioration on gas lines.

Improperly vented gas appliances allow carbon monoxide to accumulate in living spaces. This odorless, colorless substance causes illness and death, making proper venting critical for safety.

When to Schedule Your Plumbing Inspection

Schedule specialized plumbing inspection during your home purchase contingency period, typically 7-10 days after offer acceptance. This timeline allows you to identify any issues and negotiate repairs or price reductions before closing.

Don’t wait until the general property walk-through to address detailed evaluation. General inspectors may miss specialized plumbing issues that dedicated professionals identify routinely.

Schedule early enough to allow time for negotiations if significant problems surface. Last-minute discoveries leave you with fewer options and less negotiating leverage with sellers.

What Professional Plumbing Inspections Include

Comprehensive professional plumbing inspection goes far beyond what you can check during home showings. Licensed specialists use specialized tools and years of experience to identify plumbing issues invisible to untrained eyes.

Professional Assessment Components:

- Complete system evaluation from meter to sewer connection

- Pressure testing with calibrated gauges

- Drain flow testing throughout the home

- Water heater detailed assessment and safety check

- Fixture operation and leak detection

- Sewer line camera examination when appropriate

- Gas line safety review for homes with gas service

- Written report documenting all findings and recommendations

Professionals identify your plumbing system condition and helps them determine whether repairs, component replacement, or complete upgrades become necessary. This information provides negotiating power during the purchase process.

K L Contractor Plumbing Inc provides detailed written reports following all plumbing inspection services. Our documentation includes photographs, detailed descriptions of problems found, and accurate cost estimates for necessary repairs.

Negotiating Repairs After Your Inspection

Discovery of plumbing issues during assessment gives you several negotiation options. Understanding these choices helps you make decisions that protect your investment and financial interests.

Post-Assessment Options:

- Request sellers complete repairs before closing

- Negotiate purchase price reduction to account for repair costs

- Request closing cost credits for future repair work

- Ask for home warranty coverage for specific systems

- Walk away from purchase if problems exceed your tolerance

Major system failures like complete sewer line replacement or whole-house repiping justify serious price negotiations. Minor repairs like fixture replacement or supply line updates typically cost less and sellers often complete these rather than risk losing the sale.

K L Contractor Plumbing Inc works with homebuyers throughout Marietta to provide accurate repair cost estimates for negotiation purposes. Our detailed quotes give you concrete numbers for purchase price negotiations.

Moving Forward With Confidence

Buying a home without thorough plumbing inspection risks inheriting expensive problems that standard evaluations overlook. This comprehensive checklist covers the critical areas determining whether your new home provides reliable service or constant headaches.

Professional plumbing inspection costs a few hundred dollars but potentially saves tens of thousands in unexpected repairs. The investment provides peace of mind and negotiating power during the purchase process.

Schedule your home buying plumbing inspection with K L Contractor Plumbing Inc before closing on your Marietta property. Our experienced team will identify any issues and provide the detailed information you need to make confident decisions.

According to the International Association of Plumbing and Mechanical Officials (IAPMO), comprehensive plumbing assessments should be conducted by licensed professionals using industry-standard methods to ensure home safety and compliance.

Contact K L Contractor Plumbing Inc today at 404-637-2796 to schedule a comprehensive pre-purchase plumbing inspection. Let our 26 years of experience protect your investment and ensure your new home’s infrastructure meets your expectations from day one.